Sustainable cobalt

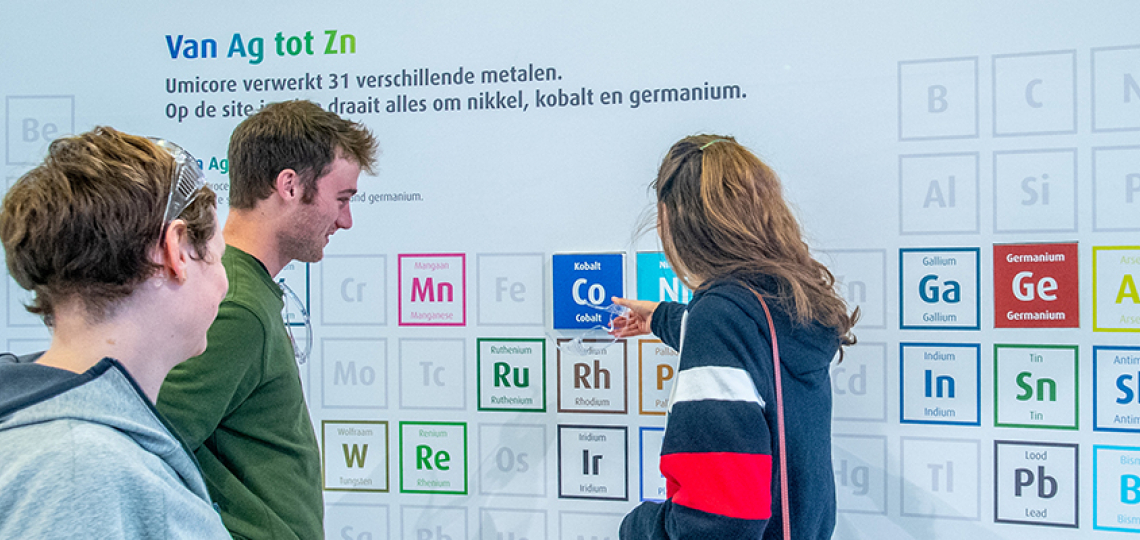

For over a century Umicore has been a world leader in cobalt products, used in many applications, from tooling to rechargeable batteries for electric cars. Some reserves of cobalt ore are in regions fraught with challenges, giving rise to unethical practices such as forced labor, poor health and safety conditions, child labor and corruption.

For us, sustainable procurement of cobalt means considering economic, environmental and social performance of our suppliers, and the social and environmental impact of the supply, in the purchase of materials. To source cobalt, we have implemented a pioneering Sustainable Procurement Framework for Cobalt and were the first to obtain external validation for our approach in this area.

The various sustainability aspects of the battery supply chain include the conditions under which raw materials are extracted and processed. Umicore is aware of the sustainability risks that are linked to the sourcing of cobalt particularly in the Democratic Republic of Congo. Often, artisanal and small-scale mining (ASM) activities are linked to issues such as human rights abuses, child labor, poor occupational health and safety conditions. In 2004 Umicore decided to exclude cobalt obtained from ASM from its supply chain.

Umicore is the first company in the world to have introduced a Sustainable Procurement Framework for Cobalt and to obtain external validation for its ethical procurement approach in this area. It aims to minimize the risk of any connection between the cobalt in its supply chain – and subsequently that of its customers – and human rights abuses or unethical business practices. Building on the specific approach to sustainable and ethical cobalt sourcing that Umicore introduced in 2004, the framework has evolved to address specific risks linked to unethical mining practices, such as child labor and poor health and safety conditions. Regular independent audits ensure that Umicore’s supply chain remains compliant with these policies.

To ensure the traceability of materials in our supply chain, we carry out detailed research and risk assessments of our suppliers. This includes visiting plants, screening policies and procedures and, if required, developing improvement programs. In 2019, Umicore again performed due diligence activities for all its purchased cobalt materials used in rechargeable batteries, tools, catalysts and several other applications. We also piloted a new third-party site audit protocol on our largest cobalt supplier and will continue with other suppliers starting in 2020.

Our cobalt refinery in Olen became the first Responsible Minerals Initiative-conformant cobalt refinery worldwide. Our newly acquired cobalt operations in Kokkola were the second recognized refinery. The Responsible Minerals Initiative aims to tackle conflict materials issues and set sustainability standards for industry.

Umicore also supports the development of traceability projects across the industry. In 2019, the Cobalt Institute launched the Cobalt Industry Responsible Assessment Framework (CIRAF), a management framework which strengthens the ability of cobalt producers and buyers to assess, mitigate, and report on responsible production and sourcing risks in their operations and supply chain. For the first time, Umicore is also reporting on our supply chain using the CIRAF, which we helped develop. The CIRAF gives industry a first opportunity to take joint action to report on sustainable cobalt. For more, see note V2.

Within the Battery Alliance, Umicore is supporting the development of a battery passport to ensure transparency on the origin of the raw materials, their transformation, use and end of life. The passport will trace the origins of battery materials and monitor them throughout their entire lifecycle on a global digital platform, to help eradicate unacceptable social or environmental practices and push unsustainable materials out of the market.

Umicore obtained, for the fifth year in a row, third-party assurance from PwC that our 2019 cobalt purchases are carried out in line with the conditions set out in the Framework. The share of cobalt from recycled origin was also reviewed as part of the assurance process and was 9% for 2019, up from 6% in 2018.

The 2019 Due Diligence Compliance Report for Cobalt Procurement, as well as previous years’ reports are available online.