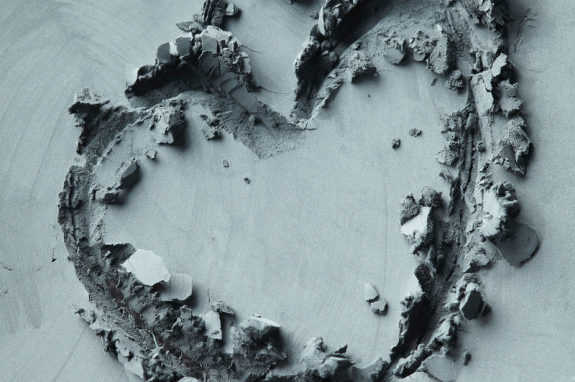

Closing the loop for cobalt in consumer devices’ batteries (2018)

Portable electronics are everywhere and integrated in the everyday life of many. Smartphones and tablets need high-performance materials to meet consumer expectations. Cobalt is an essential ingredient in delivering the required lifetime of the batteries in those devices.

The success of the telecommunication sector comes with a drawback: never has more electronic waste (e-waste) been generated. The consequences are broad: e-waste is often improperly treated, leading to health, safety and environmental issues, and, due to the absence of collection and traceability, it is difficult to know how much e-waste is treated or goes to landfills. The result is that valuable resources, like cobalt, are unnecessarily lost.

Closing the loop for the batteries is an essential step in addressing the global e-waste challenge. Moreover, it is an important step in a more responsible use of our resources and to mitigate the risk of environmental and social abuses that occur in some parts of the primary extraction industry.

By pioneering in the development of closed-loop solutions for lithium-ion batteries, Umicore contributes to the development of a responsible electronics industry.

With its technology, Umicore can recycle lithium-ion batteries into cobalt and lithium products at high recovery rates. The cobalt-containing alloy produced in the recycling process can be used as input to the refining process to re-use the metal again in new battery materials, hence Umicore closes the materials loop for cobalt entirely.

In 2018, Umicore supported one of its customers, a world leader in portable electronics, in closing its cobalt loop by recycling end-of-life batteries and production scraps to re-use the recycled cobalt in the cathode material for the customer’s batteries.

Umicore and its customer achieved an important milestone in closing the loop for electronics, an industry first.

Umicore engaged with an independent third-party to verify that the recycled units were properly recycled and tracked. Thanks to third-party verification, Umicore could provide the required evidence to the customer to demonstrate progress towards its goal of 100% recycled cobalt content in their new batteries.

Involving several of Umicore’s plants and business units, this milestone project is a great example of how close collaboration allows Umicore to excel in customer satisfaction and achieve great strides in developing sustainable business solutions. Offering a closed-loop model on cobalt in portable electronics is, again, an essential achievement for Umicore towards the objective to turn sustainability into a greater competitive advantage.

Stories

- Formula E

- Gasoline particulate filters

- Energy storage at Umicore’s Olen site

- Umicore travel and fleet policy

- Cultivating young talent

- Stationary Catalysis

- Sustainable battery materials supply chain

- Umicore Capital Market Days in Seoul, Korea

- Umicore Argentina closed the loop for cooling water

- Employee Engagement

- Closing the loop for cobalt in consumer devices’ batteries

- Umicore Hoboken integrates refugees into the workforce

- Introducing the Umicore Awards

- Innovation for a sustainable future

- Bringing the world of sustainable technologies to students

- Growing for clean mobility

- Improving gender diversity in senior management

- Powering towards a future in electric Vehicles

- Smooth integration of Haldor Topsoe’s DeNOx technology

- Environment as a catalyst for improvement

- JUMPing across borders

- Expanding to meet the clean mobility challenge

- Ensuring sustainable cobalt sourcing

- Pushing for progress on safety

- New automotive catalyst plant to enable cleaner air

- Olen: Charging for the Future

- Collaborating on new metal recovery processes